08071792702

08071792702

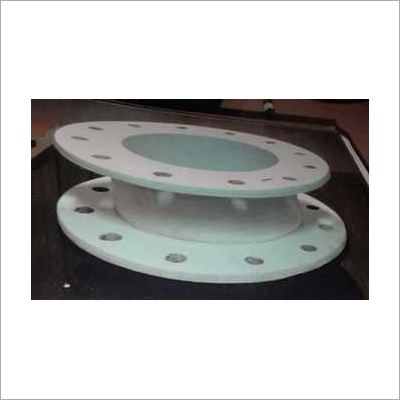

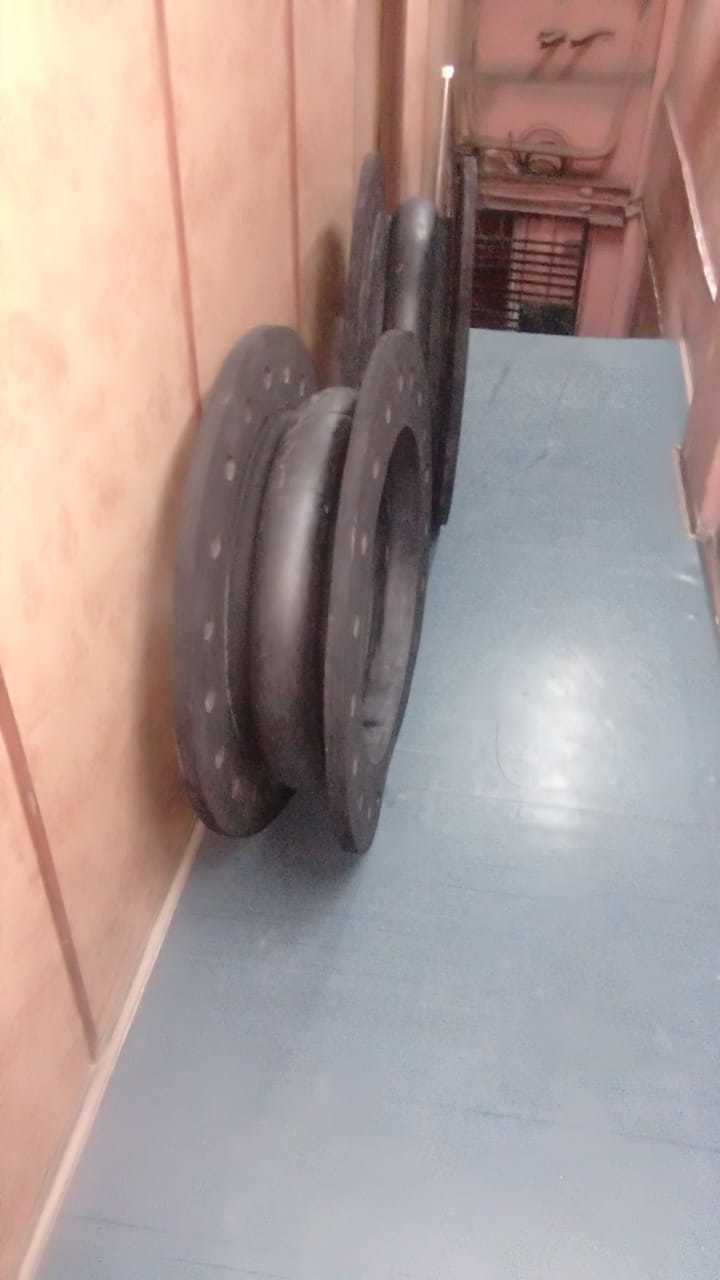

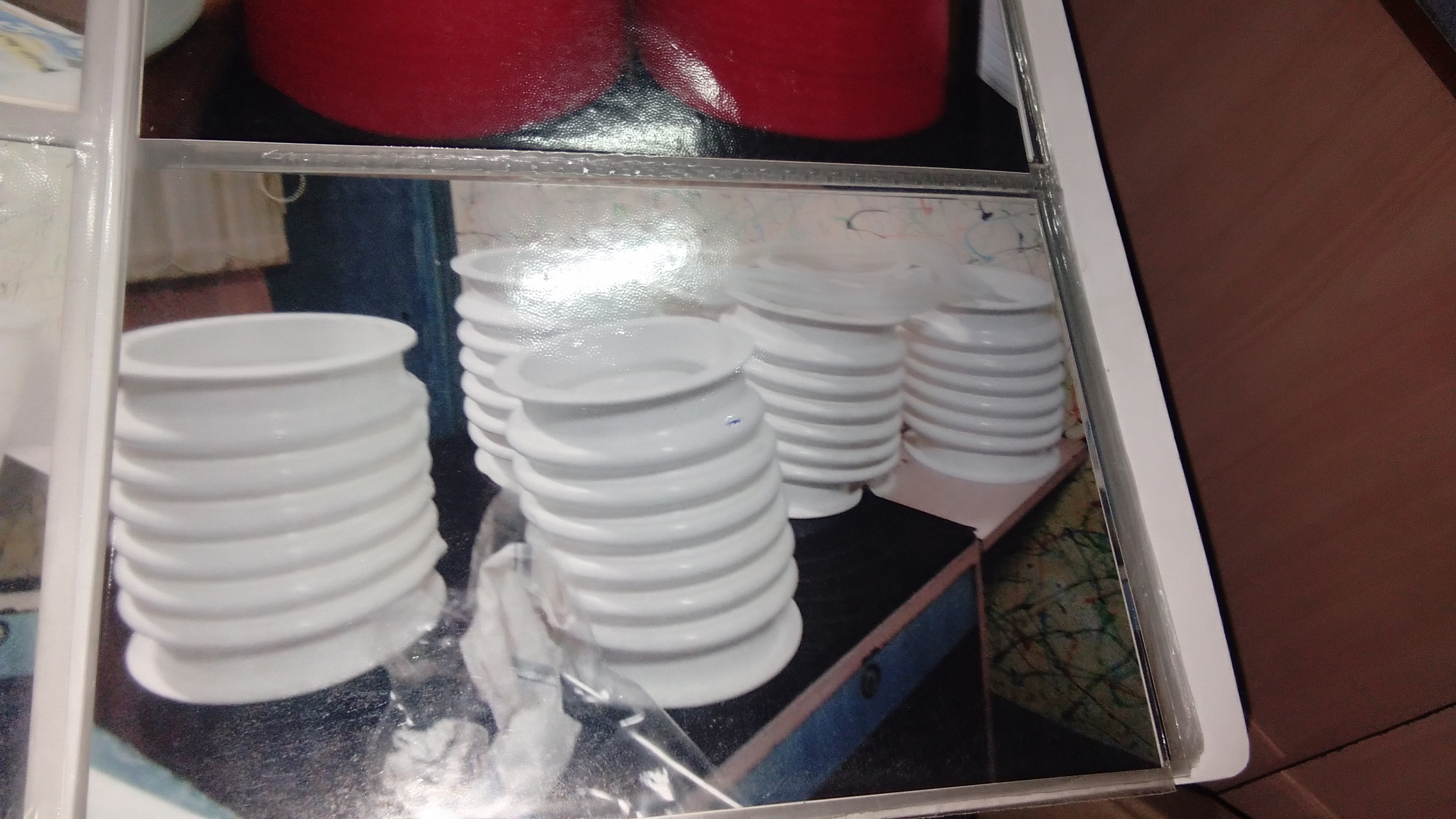

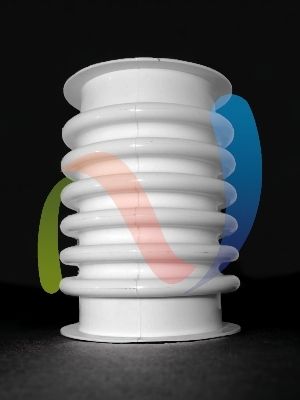

Expansion Joints

Product Details:

- Surface Treatment Polished / Galvanized / Painted

- Head Code Round

- Flange Available in Various Standards (ANSI, DIN, JIS)

- Media Water, Gas, Oil, Steam, Chemicals

- Max. Temperature -20C to 700C (Depending on Material)

- Material Stainless Steel, Rubber, PTFE, and Metal Alloys

- Technique Hot Rolled or Welded

- Click to View more

Expansion Joints Price And Quantity

- 1 Piece

Expansion Joints Product Specifications

- Axial, Lateral, Universal, Hinged, Gimbal

- -20C to 700C (Depending on Material)

- Flanged, Welded, Threaded

- Stainless Steel, Rubber, PTFE, and Metal Alloys

- Up to 40 bar / as per design

- Hot Rolled or Welded

- Water, Gas, Oil, Steam, Chemicals

- Available in Various Standards (ANSI, DIN, JIS)

- Round/Cylindrical Bellows

- Polished / Galvanized / Painted

- Round

Expansion Joints Trade Information

- 15 Piece Per Day

- 1 Week

Product Description

With a great reputation in the market, we are considered as leading manufacturers and suppliers of Expansion Joints. These assemblies are specifically designed for absorbing temperature-induced expansion and contraction of construction materials. Thus, they can easily hold parts together or for allowing movement due to grounds settlement as it absorbs vibrations as well. For its efficient and smooth working, it utilizes some accessories that include covers, liners, limit rods, and purge connectors. Moreover, the offered Expansion Joints are used for various applications and are found between sections of piping systems, buildings, bridges, railway tracks, and ships.

Product Details

| Connection | Flange |

| Material | Natural Rubber |

| Hardness | 50-63 shore |

| Section Shape | Round |

Versatile Movement Absorption

Expansion joints are designed to handle axial, lateral, and angular movements, ensuring stability and protection for connected piping systems. These features help maintain system integrity during thermal expansion, seismic activity, or vibration, making them indispensable in industrial applications. By mitigating stress and movement, they extend equipment lifespan and reduce maintenance costs.

Material and Customization Options

Manufactured using stainless steel, rubber, PTFE, and specialized metal alloys, expansion joints offer corrosion resistance and adaptability to different media and temperatures, ranging from -20C to 700C. Customers can request customized sizes, shapes, and surface treatments, enabling seamless integration with unique project requirements while maintaining compliance with performance standards.

Comprehensive Testing and Standards

Each expansion joint unit is factory tested for leak tightness, ensuring high reliability and safety. Connections are available in flanged, welded, or threaded designs, conforming to international standards like ANSI, DIN, and JIS. These rigorous tests and certification deliver peace of mind and operational efficiency for critical applications.

FAQs of Expansion Joints:

Q: How do expansion joints absorb different types of movement in piping systems?

A: Expansion joints are engineered with flexible bellows that accommodate axial, lateral, and angular movement, effectively absorbing stress caused by thermal expansion, vibration, or misalignment within piping systems. This ability prevents structural damage and supports uninterrupted fluid flow.Q: What factors influence the choice between single-ply and multi-ply bellow layers?

A: The selection depends on the applications pressure rating, movement requirements, and media type. Multi-ply bellows offer increased flexibility and fatigue resistance for demanding settings, while single-ply designs suit standard conditions where minimal movement absorption is sufficient.Q: When is an inner sleeve recommended for expansion joints?

A: An inner sleeve is advisable when the joint faces abrasive media or high velocity flows. It protects the bellow from wear, improves flow characteristics, and prolongs the products service life, especially in chemical plants, oil & gas pipelines, or power plants.Q: Where can these expansion joints be installed?

A: Expansion joints are applicable in a wide variety of locations, including HVAC installations, chemical factories, oil & gas pipelines, and power generation facilities. Their versatility in size and connection types ensures compatibility with most industrial and municipal piping systems.Q: What is the process for ensuring leak tightness in these joints?

A: Each expansion joint undergoes rigorous 100% factory leak tightness testing using industry-approved methods. These tests validate the products integrity before dispatch, ensuring reliable performance under expected operating conditions.Q: How do material and surface treatments affect corrosion resistance and temperature tolerance?

A: Corrosion resistance and temperature limits depend on the base materialstainless steel, PTFE, rubber, or metal alloysand the type of surface treatment applied, such as polishing, galvanizing, or painting. These measures optimize durability and compatibility with water, gas, oil, steam, and chemicals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+